|

|

SURFACE MOUNT TROUBLSHOOTING GUIDE

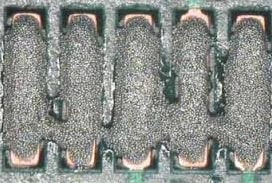

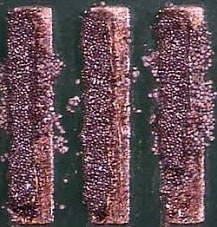

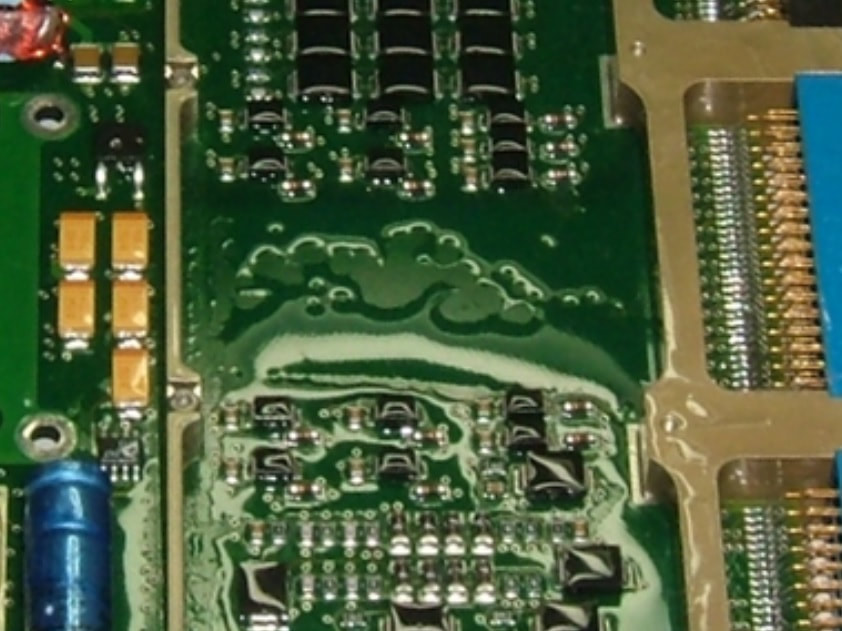

Slump

Causes: Typically due to process being run within an environment outside what is specified within datasheet.

Preventative Actions: Consider installation of temperature control module (TCM) to regulate temperature and humidity within printer. |

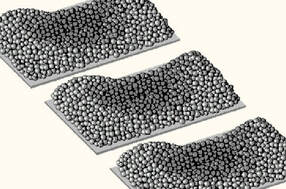

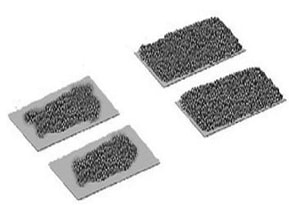

Scooping

Causes: Squeegee pressure set too high, stencil damage, apertures within stencil too large, when using low-temperature lead free paste scooping can be caused by printing too slowly.

Preventative Actions: Divide large stencil apertures. If using low-temperature lead free paste, ensure print speed fast enough. |

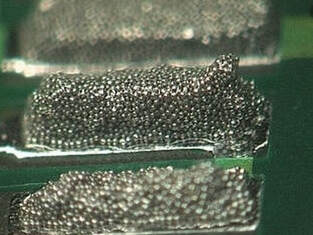

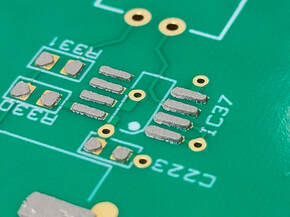

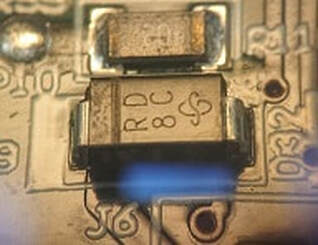

Bridging

Causes: Insufficient PCB support and/or stencil tension, poor stencil condition or cleanliness, poor gasketing between stencil and PCB, solder paste condition, solder paste slump.

Preventative Actions: Check stencil, PCB support & paste |

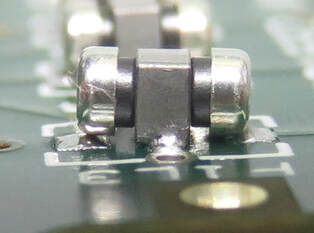

Peaking

Causes: PCB separation (snap off) speed set too high, poor stencil condition or cleanliness, stencil aperature damage.

Preventative Actions: Adjust PCB separation speed, check stencil for damage |

Bleeding

Causes: Poor gasketing between PCB and stencil, poor PCB support, squeegee pressure set too high, poor stencil condition or cleanliness.

Preventative Actions: Ensure stencil aperture size is smaller than pads on PCB, improve PCB support, reduce squeegee pressure, check stencil for damage. |

Print Misalignment

Causes: Printer alignment error, PCB shrink or stretch, insufficient PCB support.

Preventative Actions: Check alignment of PCB to stencil, ensure fiducial marks are flat and correctly positioned on stencil and PCB. |

Partial Print

Causes: Blocked stencil, poor stencil condition or cleanliness, squeegee pressure set too low, solder paste not at room temperature or not fully mixed.

Preventative Actions: Ensure paste fully mixed ideally using automatic mixer, consider using fine-grain material for stencil and/or nano-coating, check aspect ratio. |

Excessive Paste affecting small areaCauses: Poor PCB support, damaged stencil, object between PCB and stencil such as a label.

Preventative Actions: Check PCB support - ideally use adaptable system, check stencil for damage, if label has been placed close to affected area relocate. |

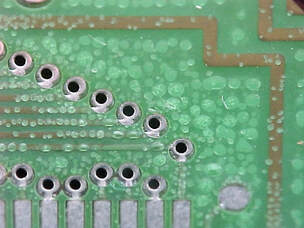

Solder Paste in Through-Holes and Vias

Causes: PCB has been misprinted and not fully cleaned, process for cleaning misprinted PCB is not effective.

Preventative Actions: If PCB is misprinted ensure it is fully cleaned ideally with automatic cleaning process with compatible chemical under pressure to clean all holes. |

Centroid File Generation ServiceAt Surface Mount Process we are offering the service to create the component placement file from Gerber data and Bill of Materials. Simply send an enquiry from the contact page

|

Component Placement Defects

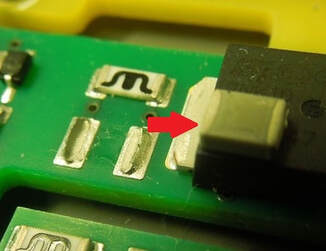

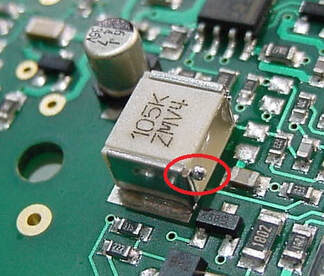

Solder Paste Pushed Off Pads

Causes: Excessive component placement pressure, faulty component placement sensor on pick and place machine, incorrect component dimensions within package library, PCB not flat due to bow and twist.

Preventative Actions: Set component placement parameters to allow for thickness of solder paste. |

Misaligned Component

Causes: Component disturbed before reflow process, component dropped instead of being placed.

Preventative Actions: Adjust component package parameters within component placement machine library to match dimensions within part datasheet, modify PCB design to ensure all parts are fully visible from above so AOI could detect fault before reflow process. |

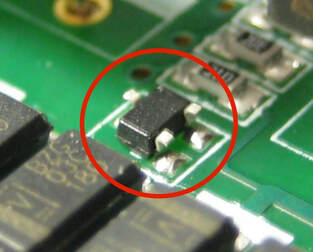

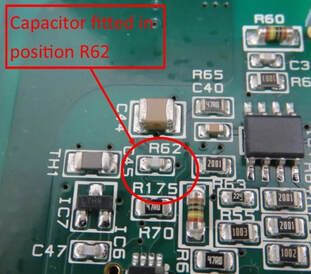

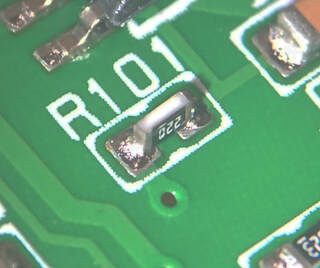

Capacitor fitted in place of Resistor

Causes: Component feeder fitted to incorrect position, when reel of components runs out incorrect reel fitted.

Preventative Actions: Implement machine load check and/or first article inspection (FAI) using smart tweezers, Consider installing electrical test module to component placement machine to detect if incorrect type or value part picked before placement. |

Reflow Soldering Defects

Unsoldered Round SMD Device

Causes: PCB surface finish not flat (HASL), component misplaced, not enough solder paste printed.

Preventative Actions: Consider using flat surface finish such as ENIG, check component parameters in placement machine, ensure enough solder paste printed, increase thickness of solder paste. |

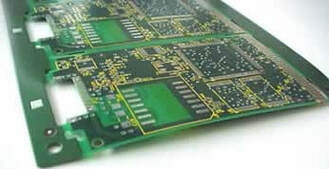

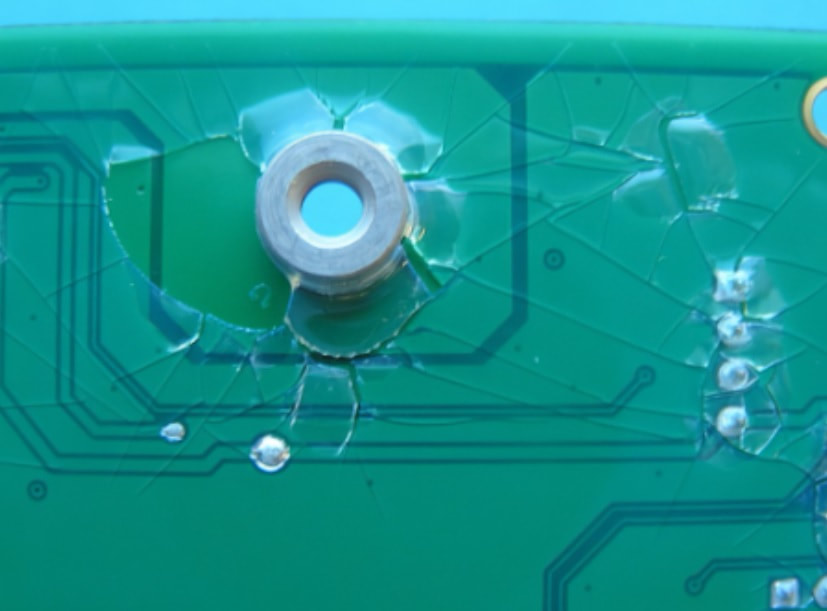

PCB Delamination

Causes: Moisture trapped within FR4 material expanding as PCB is heated by reflow process.

Preventative Actions: Pre-bake PCB's before use and consider using material with higher Tg rating - See here for more details, store PCB's in moisture cabinet. |

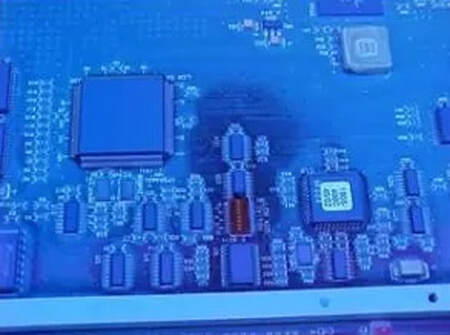

PCB Measling

Causes: Contamination under solder mask layer, moisture trapped within FR4 material expanding as PCB is heated.

Preventative Actions: Consider alternative PCB supplier, pre-bake PCB's before use and consider using material with higher Tg rating - See here for more details, store PCB's in moisture cabinet. |

Head-in-Pillow (HIP)

Causes: Excessive heat applied during preheat and soak causing flux to become exhausted before entering reflow stage, oxidised solder connections.

Preventative Actions: Reduce time and/or temperature during preheat and soak stage of profile, consider using nitrogen or higher activity solder paste. |

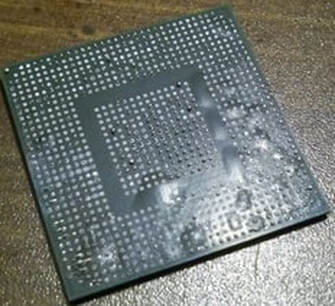

Unconnected BGA Solder JointCauses: Insufficient solder paste applied, poor PCB surface finish, component defect, PCB warped.

Preventative Actions: Check height and volume of paste deposit using 3D SPI before component placement, check PCB solderability, check quality of component, check PCB for bow and twist. |

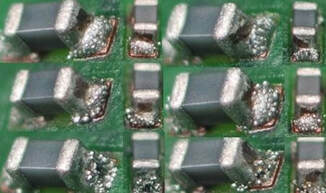

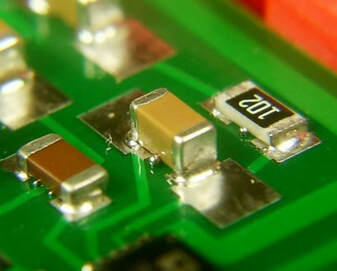

Mid-Chip Solder BallCauses: Incorrect stencil design causing some solder to become separated from the original print during component placement and reflow, incorrect PCB footprint design.

Preventative Actions: Modify stencil aperture design, modify PCB footprint design as per component datasheet. |

Component Tombstone

Causes: Copper difference either side of component footprint causing thermal imbalance, component misplacement.

Preventative Actions: Modify PCB design to balance copper, modify reflow profile to reduce delta T, improve accuracy of component placement. |

Poor PCB Solderability

Causes: Poor PCB quality during manufacture, PCB surface finish deteriorated or damaged during storage.

Preventative Actions: Consider alternative suppliers for PCB's, consider alternative surface finishes, improve method of storage for PCB's. |

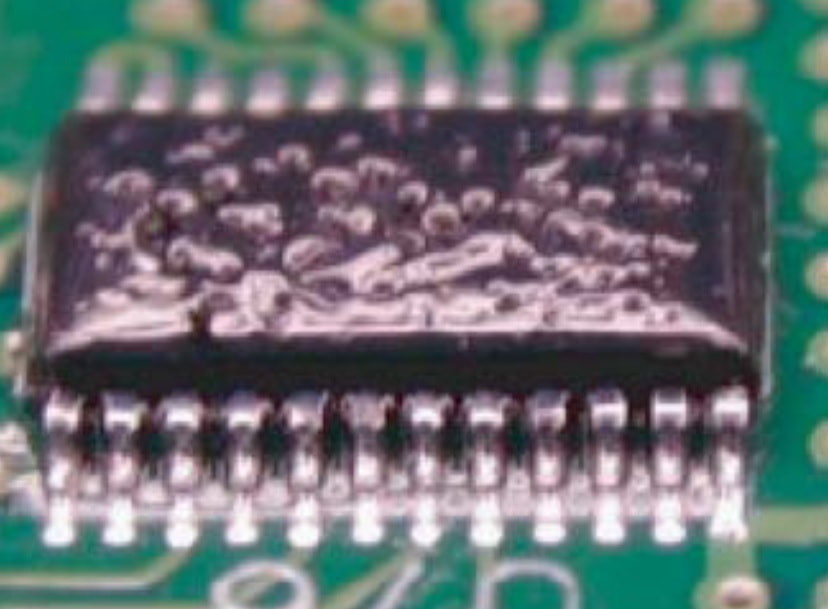

Component Popcorning

Causes: Moisture trapped within component expands as heated by reflow proces.

Preventative Actions: Store components within humidity cabinet or pre-bake before use. |

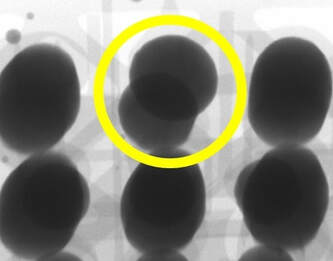

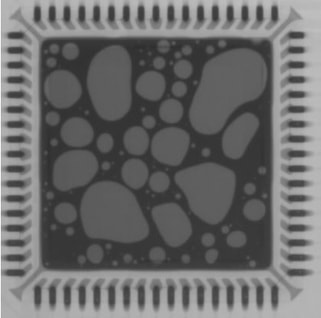

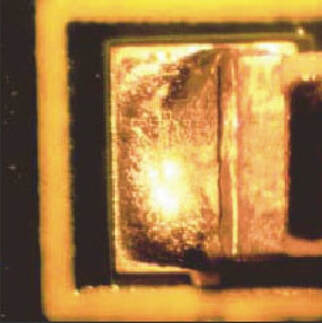

Solder Voiding Underneath Components

Causes: Volatiles released during reflow of solder paste are trapped within solder and not allowed time to escape, vias within pads contributing to gas pockets.

Preventative Actions: Allow more time when solder is molten for volatiles to escape, modify stencil design to allow more pathes for volatiles to escape, consider alternative low-voiding solder pastes, plug vias in PCB. |

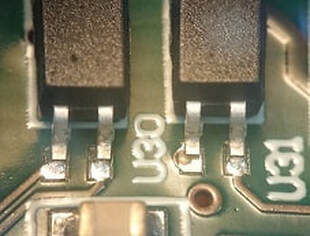

Component Lifted Lead - Coplanarity

Causes: Component damaged before placement and defect not detected by vision system within component placement machine.

Preventative Actions: Setup coplanarity check within software of component placement machine to detect bent leads. |

Poor Solder Wetting

Causes: Poor component or PCB solderability, poor quality solder paste, incorrect reflow profile.

Preventative Actions: Check PCB and component solderability, check quality of solder paste, check reflow profile to solder paste datasheet. |

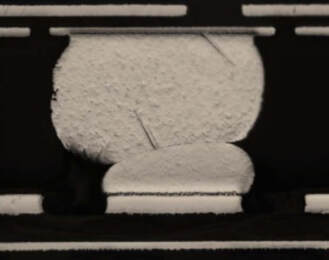

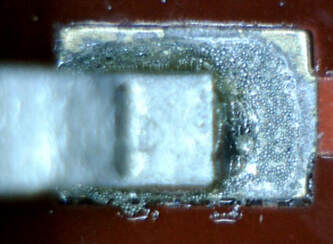

No Intermetallic Formation

Causes: Poor component solderability, poor quality solder paste, incorrect reflow profile, poor compatibility of PCB finish, solder type, and component termination material.

Preventative Actions: Check PCB and component solderability, check quality of solder paste, check reflow profile to solder paste datasheet. |

Component Billboard

Causes: Pickup error during component placement process quite often caused by feeder problems.

Preventative Actions: Check feeders on component placement machine are indexing smoothly so parts are not flipped onto their side, adjust vision system on placement machine library to detect parts picked up on their side and reject. |

Insufficient or No Solder

Causes: Error during solder paste printing process caused by insufficient solder paste on the stencil or blocked aperture.

Preventative Actions: Ensure enough solder paste is applied to the stencil and is frequently replenished, set printer to clean stencil with appropriate chemical and vacuum, inspect solder paste print before placement. |

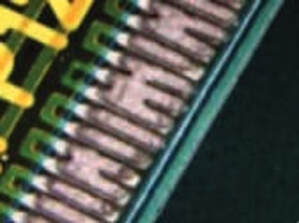

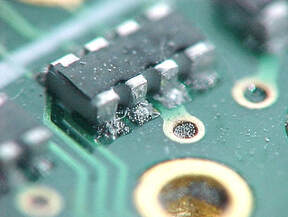

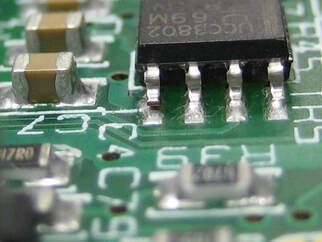

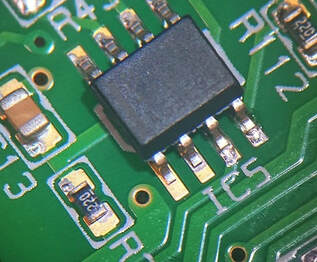

Solder Short on Fine Pitch QFP

Causes: Component misplaced, component disturbed before reflow process, misaligned solder paste print.

Preventative Actions: Check component height, vision parameters and placement speed for component package to ensure accurate placement, ensure good solder paste print using 3D SPI. |

Failure of Rohs Compliant Component

Causes: Rohs compliant component not compatible with reflow process temperature for SAC lead-free solder.

Preventative Actions: Use low temperature lead-free solder, use alternative Rohs compliant component that is compatible with SAC reflow process temperatures. |

Defects after PCB Cleaning Process

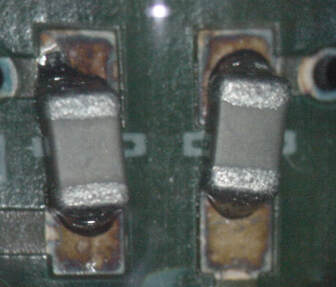

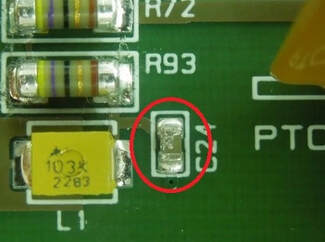

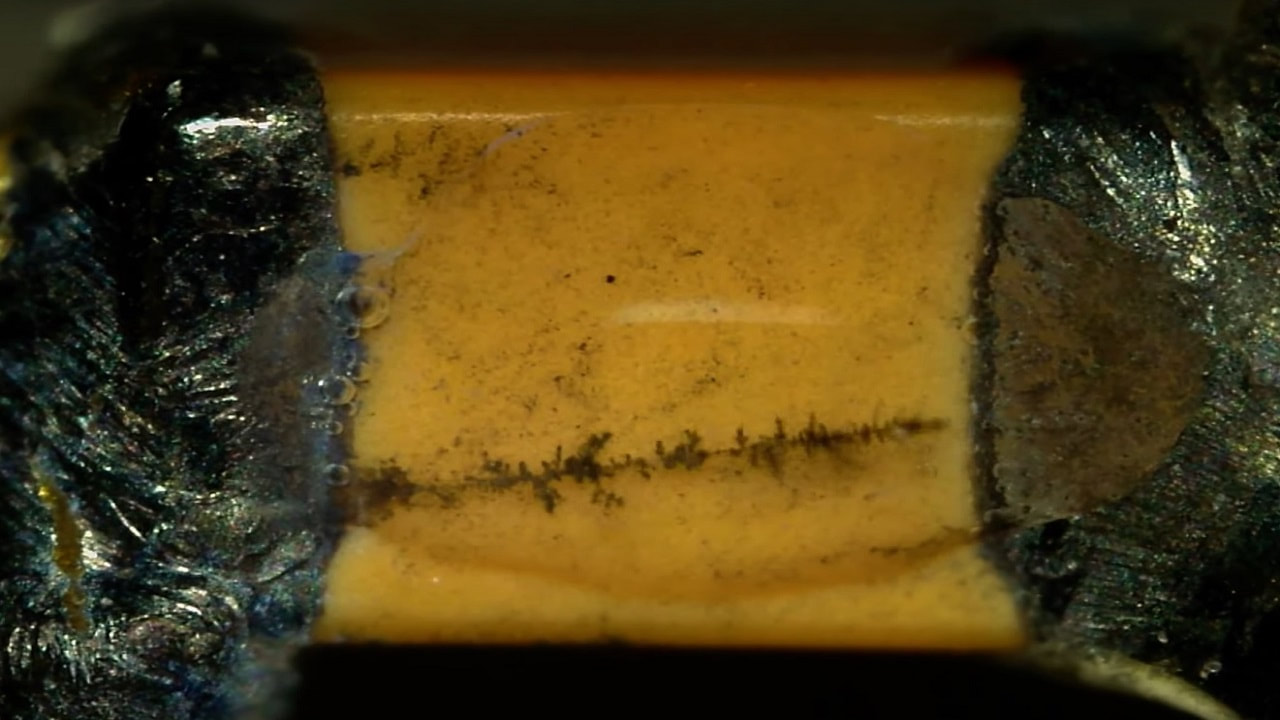

Electrochemical Migration (ECM)

Causes: Flux/cleaning chemistry residues and moisture - movement of ions in the presence of an electric field.

Preventative Actions: Ensure all flux/cleaning chemistry residues are fully removed and assembly is completely dry after PCB cleaning process. |

Defects after Conformal Coating Process

Bubbles

Causes: Improper mixing, high viscosity, contamination, excessive thickness, trapped air, poor application, inadequate drying/curing, too rapid drying/curing, trapped moisture.

Preventative Actions: Ensure conformal coating is mixed correctly, with correct viscosity, free of contamination, is applied from multiple angles, is applied using a controlled method and is dried/cured at the recommended rate. |

De-wetting

Causes: Coating incompatibility, poor coating quality, PCB surface contamination.

Preventative Actions: Check the datasheet for chosen coating material to ensure is compatible with PCB material, check coating quality and viscosity, ensure PCB has been cleaned thoroughly and is handled using gloves to avoid finger prints. |

Cracking

Causes: Excessive thickness, inadequate drying/curing process, excessive heat during drying/curing.

Preventative Actions: Control thickness during the application process, allow enough time using the correct temperature for coating to dry/cure. |

Orange Peel

Causes: Incorrect coating application process, insufficient air pressure during spray application process, incorrect viscosity, incompatible thinner.

Preventative Actions: Check coating application process, air pressure if spray application process used, ensure correct viscosity and regularly check. |

Capillary flow

Causes: Excessive coating thickness, low viscosity, varying surface tension across PCB surface being coated.

Preventative Actions: Control coating thickness during application process, ensure correct viscosity, thoroughly clean PCB before coating process. |

|

|