No intermetallic formation during reflow soldering is not a typical outcome in soldering processes, as intermetallic compounds (IMCs) are usually an integral part of the soldering reaction. Intermetallic compounds are chemical compounds formed at the interface between the solder and the metal surfaces being joined (typically the component leads and the PCB pads) during the soldering process. These compounds play a crucial role in creating strong and reliable solder joints.

Intermetallic Compound Formation:

During the reflow soldering process, solder paste is heated to its melting point, causing it to wet and bond to the metal surfaces of the component leads and the PCB pads. As the solder cools and solidifies, it forms intermetallic compounds at the interface between the solder and the metal surfaces. These IMCs are typically layers of different metallic compounds, often comprising the solder alloy and the base metal of the component leads or PCB pads.

Importance of Intermetallic Compounds:

Intermetallic compounds are essential for several reasons:

- Mechanical Strength: IMCs contribute to the mechanical strength and stability of the solder joint, helping to hold the components securely in place.

- Electrical Conductivity: They provide good electrical conductivity, ensuring the electrical connection between the component and the PCB.

- Corrosion Resistance: IMCs can improve the resistance of the solder joint to corrosion and oxidation.

- Reliability: Proper IMC formation is critical for the long-term reliability of solder joints. Without them, the solder joint may be weaker and less durable.

Issues with No Intermetallic Formation:

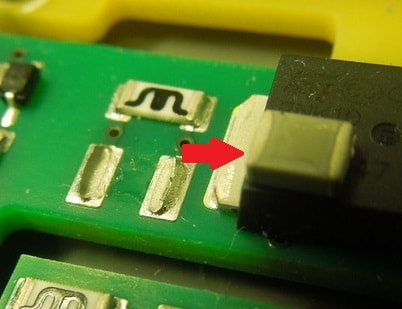

If there is "no intermetallic formation" during reflow soldering, it generally indicates a problem with the soldering process or materials. Some potential issues that could lead to this scenario include:

- Insufficient Heat: If the solder does not reach a sufficiently high temperature during reflow, it may not form IMCs properly. This can occur if the reflow profile is not properly calibrated.

- Contaminants: The presence of contaminants, such as oxides or flux residues, at the solder joint interface can inhibit the formation of IMCs.

- Incompatible Materials: If the solder alloy is not compatible with the base metals of the component leads or PCB pads, it may hinder IMC formation.

- Improper Solder Paste: The solder paste composition and quality can impact IMC formation. The paste should be compatible with the specific components and PCB materials.

In summary, intermetallic compound formation is a critical aspect of the soldering process, and the absence of IMCs during reflow soldering is generally not desirable. Properly formed IMCs contribute to the strength, electrical performance, and long-term reliability of solder joints. Therefore, soldering processes and materials are typically optimized to ensure the correct formation of intermetallic compounds during reflow soldering.