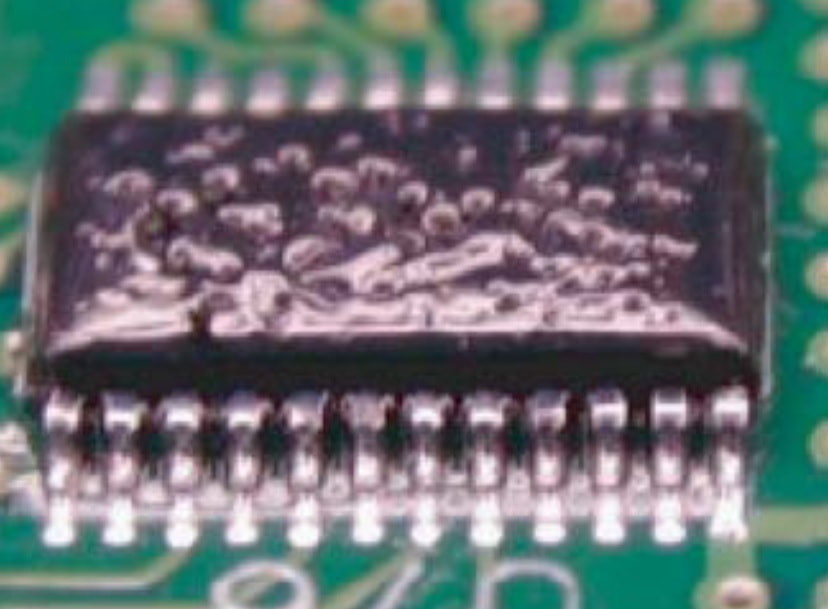

'Orange peel' in conformal coating refers to a textured surface appearance resembling the skin of an orange. This defect can negatively impact the aesthetics and, in some cases, the performance of the coating. Orange peel is typically caused by issues during the application and curing processes. Here are common reasons for orange peel in conformal coating and potential solutions:

- Incorrect Viscosity:

- The viscosity of the conformal coating material is crucial for achieving a smooth finish. If the viscosity is too high, it can lead to 'orange peel'. Check and adjust the viscosity of the coating material according to the manufacturer's recommendations.

- The viscosity of the conformal coating material is crucial for achieving a smooth finish. If the viscosity is too high, it can lead to 'orange peel'. Check and adjust the viscosity of the coating material according to the manufacturer's recommendations.

- Incorrect Thinning:

- Thinning the conformal coating material incorrectly can also result in 'orange peel'. Follow the manufacturer's guidelines for thinning, if necessary, and ensure a consistent mixture.

- Thinning the conformal coating material incorrectly can also result in 'orange peel'. Follow the manufacturer's guidelines for thinning, if necessary, and ensure a consistent mixture.

- Application Technique:

- The method of application, whether spraying, brushing, or dipping, can impact the texture of the coating. Ensure that the application technique is suitable for the chosen coating material and adjust parameters such as spray pressure and nozzle size to achieve a smoother finish.

- Incorrect Spray Gun Setup:

- Improper spray gun setup, including incorrect pressure and nozzle adjustments, can contribute to 'orange peel'. Calibrate the spray gun settings based on the coating material specifications and the desired finish.

- Improper spray gun setup, including incorrect pressure and nozzle adjustments, can contribute to 'orange peel'. Calibrate the spray gun settings based on the coating material specifications and the desired finish.

- Suboptimal Environmental Conditions:

- Factors such as temperature, humidity, and airflow can affect the application and curing of conformal coating. Ensure that environmental conditions are within the recommended range for the specific coating material.

- Improper Curing Conditions:

- Incorrect curing conditions, including temperature and duration, can contribute to 'orange peel'. Follow the manufacturer's recommendations for the curing process to achieve optimal results.

- Incorrect curing conditions, including temperature and duration, can contribute to 'orange peel'. Follow the manufacturer's recommendations for the curing process to achieve optimal results.

- Inadequate Surface Preparation:

- Poor surface preparation, such as insufficient cleaning or the presence of contaminants, can result in an uneven coating surface. Ensure the substrate is thoroughly cleaned and prepared before applying the conformal coating.

- Material Compatibility:

- Ensure that the conformal coating material is compatible with the substrate and any previously applied coatings. Incompatibility can lead to irregularities in the coating surface.

- Material Composition:

- Some conformal coating materials may inherently exhibit 'orange peel' due to their composition. Consider using alternative materials with different properties if 'orange peel' is a persistent issue.

- Some conformal coating materials may inherently exhibit 'orange peel' due to their composition. Consider using alternative materials with different properties if 'orange peel' is a persistent issue.

- Testing and Optimization:

- Conduct test runs with different settings and parameters to optimize the coating process and minimize orange peel. Adjust variables such as spray distance, speed, and flow rate to achieve the desired finish.

If 'orange peel' is observed, it may be necessary to rework the components by addressing the root cause of the issue and adjusting the application parameters accordingly. Always refer to the guidelines provided by the conformal coating material manufacturer for specific recommendations based on the material used.