A RoHS (Restriction of Hazardous Substances) compliant component that cannot withstand RoHS reflow temperatures presents a significant challenge in electronics manufacturing. RoHS compliance requires that electronic components and assemblies do not contain or use certain hazardous substances, such as lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (CrVI), and others.

The primary issue with a RoHS compliant component that cannot withstand RoHS reflow temperatures is that the reflow soldering process involves heating the assembly to relatively high temperatures, typically in the range of 220°C to 260°C (428°F to 500°F), depending on the specific solder alloy used. These temperatures are necessary for melting and reflowing the lead-free solder used in RoHS-compliant assemblies.

Here are some reasons why a RoHS compliant component might not withstand RoHS reflow temperatures:

The primary issue with a RoHS compliant component that cannot withstand RoHS reflow temperatures is that the reflow soldering process involves heating the assembly to relatively high temperatures, typically in the range of 220°C to 260°C (428°F to 500°F), depending on the specific solder alloy used. These temperatures are necessary for melting and reflowing the lead-free solder used in RoHS-compliant assemblies.

Here are some reasons why a RoHS compliant component might not withstand RoHS reflow temperatures:

Low Melting Point Materials:

Some components, particularly those designed before the widespread adoption of RoHS standards, may contain materials with low melting points. For example, certain plastic components, connectors, or adhesives may deform, melt, or sustain heat damage at the elevated temperatures of reflow soldering.

Thermal Sensitivity:

Components with sensitive semiconductor devices, sensors, or other heat-intolerant materials may not survive the reflow process. High temperatures can damage or alter the properties of these materials, rendering the component non-functional.

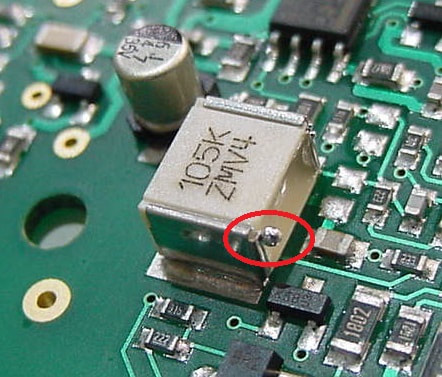

Non-Solderable Materials:

RoHS-compliant components that are not designed for surface mount technology (SMT) soldering may not have solderable leads or terminations. Attempting to subject such components to reflow soldering could result in poor solder joints or damage to the component.

Incompatible Materials:

Some RoHS-compliant components may still contain materials that are not compatible with the temperatures of RoHS reflow soldering, leading to potential component failures or reliability issues.

Addressing the Challenge:

When faced with RoHS-compliant components that cannot withstand RoHS reflow temperatures, manufacturers may need to consider alternative soldering processes or assembly methods. These alternatives could include:

Low-Temperature, Lead-Free Solder Alloys:

Low-temperature, lead-free solder alloys are designed to provide soldering solutions that require lower melting points compared to traditional lead-free solders. These alloys are especially useful for soldering temperature-sensitive components or substrates that cannot withstand the higher temperatures typically associated with lead-free soldering.

Through-Hole Soldering:

Components with temperature-sensitive materials can be hand-soldered or wave soldered using lead-free solder alloys that have lower melting points than those used in reflow soldering.

Selective Soldering:

For components that are particularly sensitive, selective soldering machines can be used to target only specific areas for soldering while protecting the rest of the component.

Adhesive or Mechanical Attachment:

In some cases, components can be attached to the PCB using adhesives or mechanical fasteners rather than soldering. This approach avoids exposing the component to reflow temperatures.

Component Replacement:

If alternative assembly methods are not feasible, component replacement with RoHS-compliant equivalents that can withstand reflow temperatures may be necessary.

In summary, RoHS compliance is essential for electronics manufacturing, but when faced with RoHS-compliant components that cannot withstand reflow temperatures, manufacturers must carefully evaluate their options and consider alternative assembly methods to ensure the reliability and functionality of their electronic products.