Setting up a Conformal Coating Production Facility

The set up of a turnkey conformal coating production line, whether it is a batch or inline process, has many similar characteristics. Whether the coating application is based around a high volume selective coating robot or a batch dip coating process, the rules and requirements tend to be the same.

General Requirements

Any coating facility will need the basic requirements put in place that would be standard for any piece of electronic manufacturing process. These include ESD systems, facilities for the machines, the environmental requirements and the normal Health & Safety (HSE) considerations. The first two are straightforward and are not considered here. However, the last two need to be considered in more depth.

Health & Safety (HSE)

HSE tends to be more important for conformal coatings since in general the coatings themselves are

hazardous, or the way they are applied makes them potentially harmful to operators. If they are solvent based coatings, then extraction to remove the fumes is very important. Most equipment will have minimum requirements for extraction to be fitted and these guidelines should be followed.

If the coatings are not solvent based, then there can be other hazards. A popular conformal coating method of application is UV cure. However, two hazards immediately come out in this technology. The first is the UV light itself since it is highly harmful to people if seen and therefore shielding has to be good around the UV cure system. The second is the ground level ozone that can be created by the UV cure process. Again, this is highly dangerous to operators and extraction is needed to remove it from the area.

Beyond UV cure there is also spraying of conformal coating. Atomising a liquid, even if it is not solvent based, can be hazardous to operators and their lungs. Therefore, the equipment used, and more importantly, the way the ventilation works around this equipment is very important.

So, if extraction is required then it is critical to follow the local HSE advice on how this is fitted and the type of extraction. Machine manufacturers supply data based upon the system they rate their system. For example, the CE system is used in Europe. But, this may vary in North America. A typical mistake made is to use normal extraction rather than an explosion proof version. In Europe and many other areas this would be illegal so care has to be taken in this selection.

hazardous, or the way they are applied makes them potentially harmful to operators. If they are solvent based coatings, then extraction to remove the fumes is very important. Most equipment will have minimum requirements for extraction to be fitted and these guidelines should be followed.

If the coatings are not solvent based, then there can be other hazards. A popular conformal coating method of application is UV cure. However, two hazards immediately come out in this technology. The first is the UV light itself since it is highly harmful to people if seen and therefore shielding has to be good around the UV cure system. The second is the ground level ozone that can be created by the UV cure process. Again, this is highly dangerous to operators and extraction is needed to remove it from the area.

Beyond UV cure there is also spraying of conformal coating. Atomising a liquid, even if it is not solvent based, can be hazardous to operators and their lungs. Therefore, the equipment used, and more importantly, the way the ventilation works around this equipment is very important.

So, if extraction is required then it is critical to follow the local HSE advice on how this is fitted and the type of extraction. Machine manufacturers supply data based upon the system they rate their system. For example, the CE system is used in Europe. But, this may vary in North America. A typical mistake made is to use normal extraction rather than an explosion proof version. In Europe and many other areas this would be illegal so care has to be taken in this selection.

Environment

Conformal coatings are sensitive to the environment that they are processed. The coating room area should be clean & dust free since PCBs are susceptible to particles sticking to the drying coating. What level of cleanliness is provided is down to the requirements of the customer or manufacturer. However, the cleaner the facility, the fewer the issues there are in meeting manufacturing standards like the IPC-A-6101.

The temperature range should be reasonably controlled within sensible limits since the viscosity of the

conformal coating will vary with temperature. This can really disrupt a coating line where a change in viscosity due to room temperature changes adjusts the coating performance.

Another critical point is the humidity. This may need to be controlled to be above 35% (for ESD reasons) and <55% due to moisture issues. This is because having a high humidity can affect the coating integrity and the application method producing dull coating thickness and entrapping moisture within the coating itself.

The temperature range should be reasonably controlled within sensible limits since the viscosity of the

conformal coating will vary with temperature. This can really disrupt a coating line where a change in viscosity due to room temperature changes adjusts the coating performance.

Another critical point is the humidity. This may need to be controlled to be above 35% (for ESD reasons) and <55% due to moisture issues. This is because having a high humidity can affect the coating integrity and the application method producing dull coating thickness and entrapping moisture within the coating itself.

Production line requirements

The production line, whether this is an operator brush coating printed circuit boards (PCBs) or an inline spray coating process can be made up of several stages (not all are mandatory). These are:

- Boards In

- Inspection

- Cleaning

- Masking

- Pre Coating Inspection

- Coating Application

- Drying / Curing

- De-Masking

- Inspection

- Boards Out

Boards In:

This is simply an area defined for the PCBs delivered to the coating area ready for processing.

Inspection:

Inspecting the PCBs before starting the process helps stop the line if there is a problem before too much work has been done upstream. It also identifies which PCBs are to be coated, the material to be used and how they are to be coated. This can be done automatically as part of the production process or completed by the operator.

Cleaning:

Cleaning circuit boards before coating may or may not be required. This is a decision that has to be made earlier on, perhaps in the design stage before production actually starts. The cleaning protocol is for the engineers to decide.

However, if you do clean, it may be worth considering a few guidelines:

• Ensure that the cleaning process does not add more contaminants to the PCB than it started with. For

example, make sure the rinsing of the cleaning fluid from the PCB is successful and that the rinse

water is DI water and high enough purity not to add ionic contaminants to the PCB.

• The PCBs are dry enough for the coating process and not leave water entrapped under components

which could impede the coating application.

• If the intention is to clean then ensure the cleaning process actually removes residues that cause

defects like de-wetting to minimise finishing at the end of the process

Again, this is for the engineers to decide and the consideration of whether you need to clean your circuit boards for conformal coating is a whole topic on its own.

However, if you do clean, it may be worth considering a few guidelines:

• Ensure that the cleaning process does not add more contaminants to the PCB than it started with. For

example, make sure the rinsing of the cleaning fluid from the PCB is successful and that the rinse

water is DI water and high enough purity not to add ionic contaminants to the PCB.

• The PCBs are dry enough for the coating process and not leave water entrapped under components

which could impede the coating application.

• If the intention is to clean then ensure the cleaning process actually removes residues that cause

defects like de-wetting to minimise finishing at the end of the process

Again, this is for the engineers to decide and the consideration of whether you need to clean your circuit boards for conformal coating is a whole topic on its own.

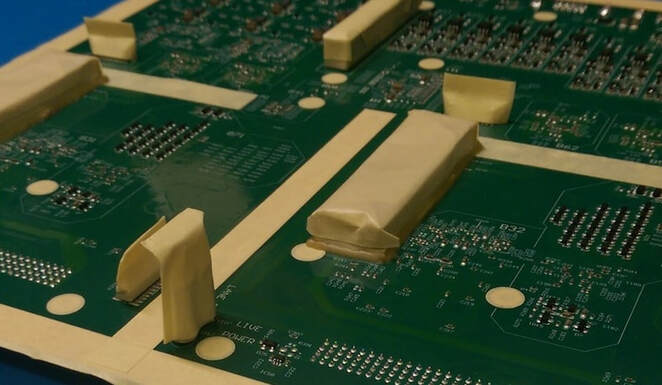

Masking:

Masking may not be required. However, there are very few circuit boards in the world that can be completely coated all over and have no areas that must not be coated. Some components on PCBs generally need to avoid having conformal coating applied to them and therefore this gives the engineers two options:

1. You can avoid coating the component or area using a selective spray or dip system.

2. You can apply some form of masking that the coating can be applied to and remove the masking materials after application.

Again, engineers need to consider their options on whether to use conformal coating masking.

1. You can avoid coating the component or area using a selective spray or dip system.

2. You can apply some form of masking that the coating can be applied to and remove the masking materials after application.

Again, engineers need to consider their options on whether to use conformal coating masking.

Pre-Coating Inspection:

It is more efficient to double check the masking process is correct before the coating application rather than repair the PCB after the process goes wrong because the masking was incorrect. This check can be manual or automated but it is highly recommended.

Coating Application:

The one stage that cannot be avoided is the coating applied to the PCB. There are many different methods for applying conformal coatings and probably the most important factor in all of them is training. The operator needs to understand the process to be able to work correctly.

Here are a few key points on the most popular methods:

Here are a few key points on the most popular methods:

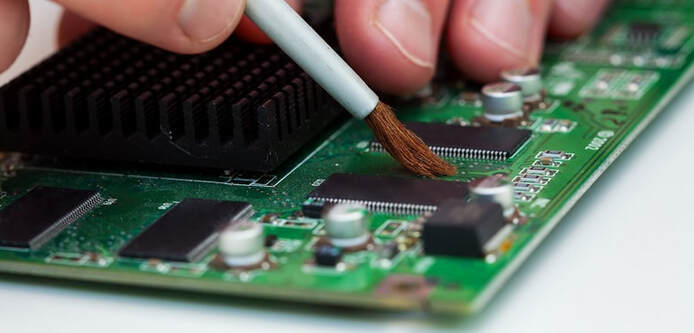

Brushing

Brush coating appears to be one of the simplest methods in conformal coating application. However, it is not easy to do well. With good technique it is possible to be highly effective and meet all the requirements of standards like the IPC specification.

Key points include:

• Create an environment suitable for brushing that is similar to the finishing and inspection stages. Good UV lighting and extraction (solvent based coatings) can make a massive difference in performance of operators over a period of time.

• Train the operator to develop the brush coating technique to minimise defects that are easily created

if the coating is applied wrongly.

• Control the viscosity of the conformal coating as this may change with time and again lead to poorer

application performance.

Key points include:

• Create an environment suitable for brushing that is similar to the finishing and inspection stages. Good UV lighting and extraction (solvent based coatings) can make a massive difference in performance of operators over a period of time.

• Train the operator to develop the brush coating technique to minimise defects that are easily created

if the coating is applied wrongly.

• Control the viscosity of the conformal coating as this may change with time and again lead to poorer

application performance.

Dipping

Dip coating can be hand dipping in a tub of conformal coating or a more formal controlled process using a dipping system. In terms of process, the key factors for control of coating application are the viscosity and withdrawal speed of the dipping machine. If you control these factors then you can control the coating thickness on the circuit board. Consider that if you are using a dip system how you handle the dripping PCBs and the control of the evaporating solvents if the coatings give off fumes.

Batch Spraying / Aerosol

When spraying with an aerosol or a spray gun in a spray booth there are several key points to consider.

• The dominant factor is operator training. This is a semi-skilled process and the application of conformal coating by hand spray is not simple.

• In general, it is far better to apply several thin layers of coating than one thick layer. This is due to problems like bubble entrapment and skinning of the coating.

• You can achieve a great finish with spraying if the operator is skillful. You can also minimise your processing after application in de-masking and touch-up if the coating is applied correctly.

• The conformal coating thickness is controlled by the operator. Ultimately good training is crucial and a method for monitoring coating thickness application is developed.

• The dominant factor is operator training. This is a semi-skilled process and the application of conformal coating by hand spray is not simple.

• In general, it is far better to apply several thin layers of coating than one thick layer. This is due to problems like bubble entrapment and skinning of the coating.

• You can achieve a great finish with spraying if the operator is skillful. You can also minimise your processing after application in de-masking and touch-up if the coating is applied correctly.

• The conformal coating thickness is controlled by the operator. Ultimately good training is crucial and a method for monitoring coating thickness application is developed.

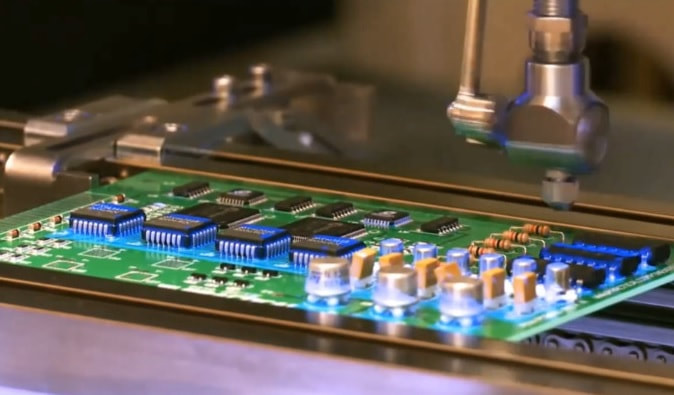

Selective Robot

Robotic coating is the dominant application method in conformal coating for high-volume production. It can eliminate or minimise masking needs, especially if the PCB is designed for the process. Again, key

factors include operator training in the use of the system since ultimately it can be a complex machine and to get the best from it requires the operator to understand the process.

factors include operator training in the use of the system since ultimately it can be a complex machine and to get the best from it requires the operator to understand the process.

Drying / Curing:

A conformal coating is a wet process (unless you use Parylene) and therefore the coating has to dry.

For example, a solvent-based acrylic coating will dry by evaporating the solvents away from the PCB. During this time the PCB is wet and could get contaminated by airborne particulates or be accidentally touched by operators. So, either the machine itself or the conveyors need to shield it from the environment, or the PCBs need to be stored away until dry.

However, if the coating needs curing fast, with UV light or heat for example, then an extra process and production systems such as UV light conveyors or inline infrared convection ovens need to be included.

For example, a solvent-based acrylic coating will dry by evaporating the solvents away from the PCB. During this time the PCB is wet and could get contaminated by airborne particulates or be accidentally touched by operators. So, either the machine itself or the conveyors need to shield it from the environment, or the PCBs need to be stored away until dry.

However, if the coating needs curing fast, with UV light or heat for example, then an extra process and production systems such as UV light conveyors or inline infrared convection ovens need to be included.

De-masking:

Like masking, there is skill in removing the masking materials and ensuring the final finished PCB is fit to pass the inspection criteria. Work instructions are needed along with training on the specific methods of finishing to ensure this can be achieved. Again, the work environment is critical and creating the correct area really helps.

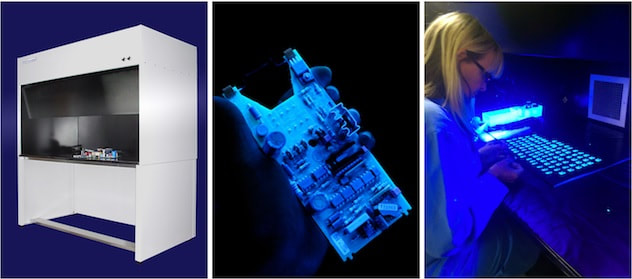

Inspection

Ultimately, when the PCB is coated and finished, you want to know if the product meets the inspection criteria. This conformal coating inspection can be done manually or automatically depending on the volume of PCBs and the level of sophistication required. Again, it is down to operator training and using the right equipment to ensure that this is possible. As well as visual inspection, it is a common practice to check the adhesion of the conformal coating to the PCB - details can be seen here.

Also, at this stage it is possible to measure factors like coating conformal thickness to check that the criteria are met. There are coating conformal thickness measurement system available to do this that if used correctly will give you very accurate readings

Also, at this stage it is possible to measure factors like coating conformal thickness to check that the criteria are met. There are coating conformal thickness measurement system available to do this that if used correctly will give you very accurate readings

Conclusion

Setting up a conformal coating facility is a straightforward process as long as all factors are considered. In general, a key factor is operator training. Get this right and many of the problems that could occur during production will be avoided. After training, setting the facility up correctly with the right systems, tools and process controls also ensures a smooth running production

An Increase in Efficiency and Productivity

It’s a shocking statistic to read that within the electronics industry many surface mount operations, particularly within the sub-contract manufacturing sector, run as low as 20% efficient.

There are many reasons that contribute to this figure but it fundamentally means that only 20% of the capital investment is being utilized. Financially speaking, this will lead to a higher cost of ownership and a slower return on investment. For the customer, it can cause longer lead times for their product and therefore the business will not be as competitive in the market place.

With production efficiencies at this level there will be many knock-on effects that will have an impact on the business such as larger batch sizes, more parts in stock, more assemblies in WIP (work in progress) and slower reaction times to customer change requirements.

With all this in mind there is a strong incentive to improve efficiency while maintaining quality.

There are many reasons that contribute to this figure but it fundamentally means that only 20% of the capital investment is being utilized. Financially speaking, this will lead to a higher cost of ownership and a slower return on investment. For the customer, it can cause longer lead times for their product and therefore the business will not be as competitive in the market place.

With production efficiencies at this level there will be many knock-on effects that will have an impact on the business such as larger batch sizes, more parts in stock, more assemblies in WIP (work in progress) and slower reaction times to customer change requirements.

With all this in mind there is a strong incentive to improve efficiency while maintaining quality.

We also offer a general consultation service to discuss any particular challenge you may be facing.

If this of interest please send a message using the Contact Page

If this of interest please send a message using the Contact Page