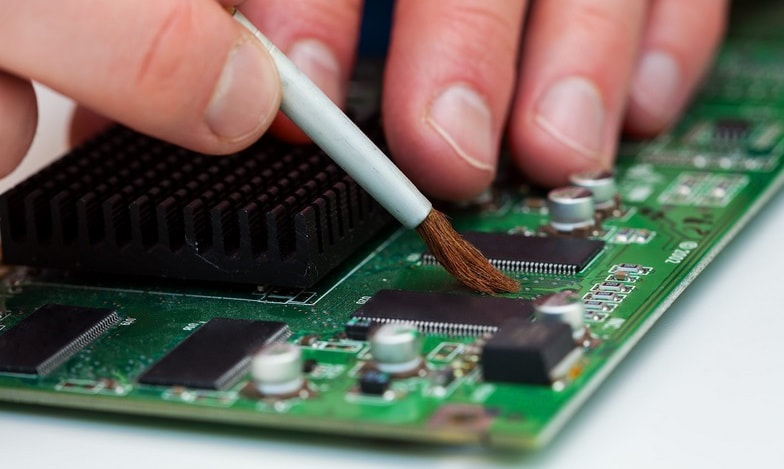

Applying conformal coating by brushing is a manual method that involves using a brush to evenly coat the surface of electronic assemblies with a protective material. This method is suitable for small-scale, prototype or rework applications where automated processes may not be practical. Here's a step-by-step explanation of the process:

- Preparation:

- Ensure that the electronic assembly is clean and free from any contaminants, residues, or flux. Cleaning may involve using appropriate solvents or cleaning agents to achieve a pristine surface.

- Masking:

- Identify and mask off any components or areas that should not be coated, such as connectors, switches, or sensitive devices. Use masking tapes or other protective materials.

- Conformal Coating Material Selection:

- Choose the appropriate conformal coating material based on the specific requirements of the application. Common types include acrylics, urethanes, silicones, and epoxy-based coatings.

- Viscosity Check:

- Ensure that the viscosity of the conformal coating material is suitable for brushing. Viscosity affects the ease of application and the coating thickness. If necessary, the material can be thinned to achieve the desired viscosity.

- Brush Selection:

- Select a high-quality, clean brush suitable for the application. The brush should be compatible with the conformal coating material and free from contaminants.

- Coating Application:

- Dip the brush into the conformal coating material and apply an even coat to the surface of the electronic assembly. Use smooth, controlled brush strokes to ensure uniform coverage.

- Drying Time:

- Allow the coated assembly to air dry or follow the specific curing instructions provided by the conformal coating material manufacturer. The drying time can vary depending on the coating type and environmental conditions.

- Inspection:

- After the coating has dried or cured, inspect the assembly for uniform coverage, ensuring that all coated areas are adequately protected. Check for any defects, such as bubbles, runs, or uneven coatings.

- Masking Removal:

- If masking was applied, carefully remove the masking materials to expose the protected areas. Take care not to damage the coated surface during this process.

- Final Inspection and Testing:

- Conduct a final inspection to ensure that the conformal coating meets the required standards. Additionally, perform electrical testing to verify that the coated components function as intended.

While brushing is a manual application method, it still requires attention to detail to achieve a reliable and consistent conformal coating. Following the manufacturer's guidelines for the specific conformal coating material is crucial to ensure proper application and performance.