THROUGH HOLE TROUBLSHOOTING GUIDE

Insufficient Hole Fill

Possible Causes: Inadequate flux, topside PCB temperature too low, wave height to low, lead-to-hole ratio too small, PCB contains solder joints connected to internal ground planes.

Preventive Actions: Verify flux deposition, verify preheat temperature, check wave height, check lead-to-hole aspect ratio, verify internal ground planes |

Insufficient Wetting

Possible Causes: Inadequate flux, dwell time too short, topside PCB temperature too low, poor solderability, contamination

Preventive Actions: Verify flux deposition, reduce drag speed/Increase solder time, verify preheat temperature, check component for contamination, check board contamination |

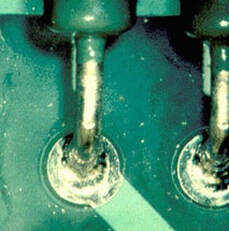

Blow Holes and Voids

Possible Causes: Topside PCB temperature too low, flux carrier outgassing, moisture in PCB, poor through-hole plating

Preventive Actions: Verify topside PCB temperature, verify flux deposition and required preheat temperature, check for moisture in laminate - prebake if necessary, check though-hole plating |

Solder Balls (Attached firmly to solder mask)

Possible Causes: Excessive flux, topside PCB temperature too

low, solder temperature too high, solder mask porosity Preventive Actions: Reduce amount of flux, verify topside PCB temperature, consider using lower temperature lead-free alloy, consider alternative solder mask material |

Sunken Solder Joints

Possible Causes: Lead-to-hole ratio too large, moisture in PCB, flux carrier outgassing, topside PCB temperature too low, poor through-hole plating, poor solderability

Preventive Actions: Reduce lead-to-hole ratio, check for moisture in laminate - prebake if necessary, verify topside PCB temperature, check though-hole plating, check component for contamination |

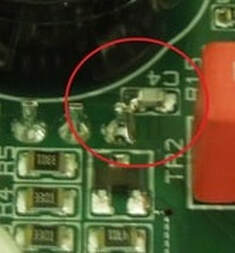

Adjacent Component Solder Short

Possible Causes: Inadequate TH to SMT clearance, lead length too long, solder nozzle movement, solder nozzle peel-off movement

Preventive Actions: Implement keep-out DFMA guidelines, reduce lead protrusion length, re-program nozzle movement, re-program peel-off movement |