What's the best way to support a PCB during assembly? |

|

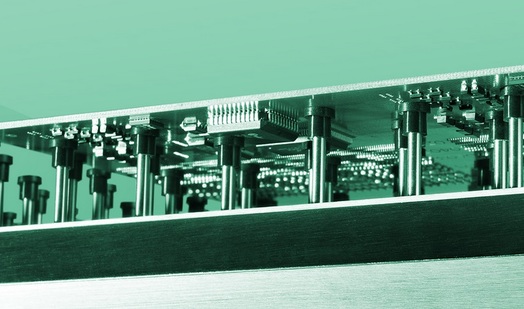

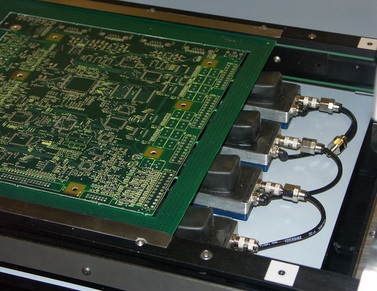

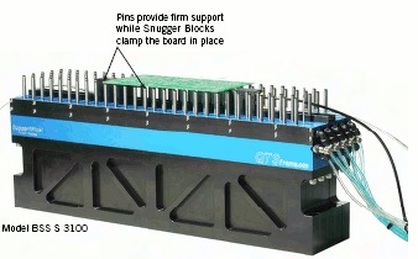

As PCB assemblies using surface mount technology have increased in complexity and become more densely populated it is important to fully support PCB’s during assembly to achieve a repeatable surface mount process. Ideally every PCB to be assembled would have its own custom support tooling but this would be a significant expense and require planning well ahead of production to allow time for design and manufacture.

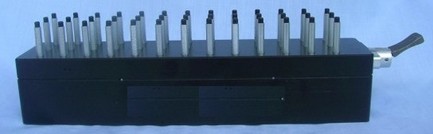

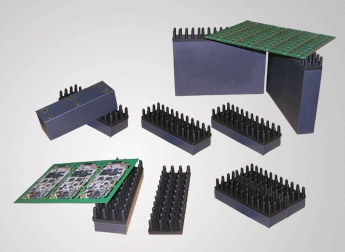

There are a number of PCB support systems available on the market to make it possible to obtain the level of flexibility required for today’s manufacturing environment.

There are a number of PCB support systems available on the market to make it possible to obtain the level of flexibility required for today’s manufacturing environment.

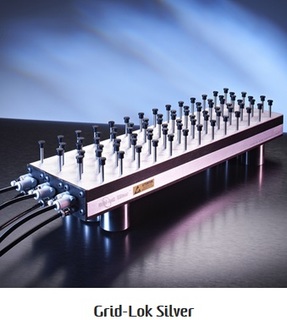

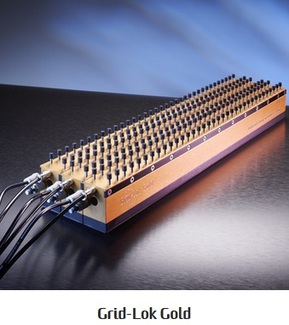

DEK - Grid-Lok

Production Solutions - Red-E-Set

Novatec - Vacunest

On Board Solutions - QTS Adaptive PCB Support System

Quik-Tool

LTC - VarioGrid

LTC - FiberFlex

Formagrind - Gel Bar System

Dobeter - PCB rubber support

Count on Tools - ezLOAD PCB support system

Crostu - Rubber supporter

Modular PCB support for single sided assemblies

All the above solutions can be used for single or double sided assemblies but due to cost are generally bought for double sided assemblies.

For single sided assemblies simpler more cost effective solutions are available such as the one shown below - Click here for more detail

For single sided assemblies simpler more cost effective solutions are available such as the one shown below - Click here for more detail

|

Return to Home Page

|