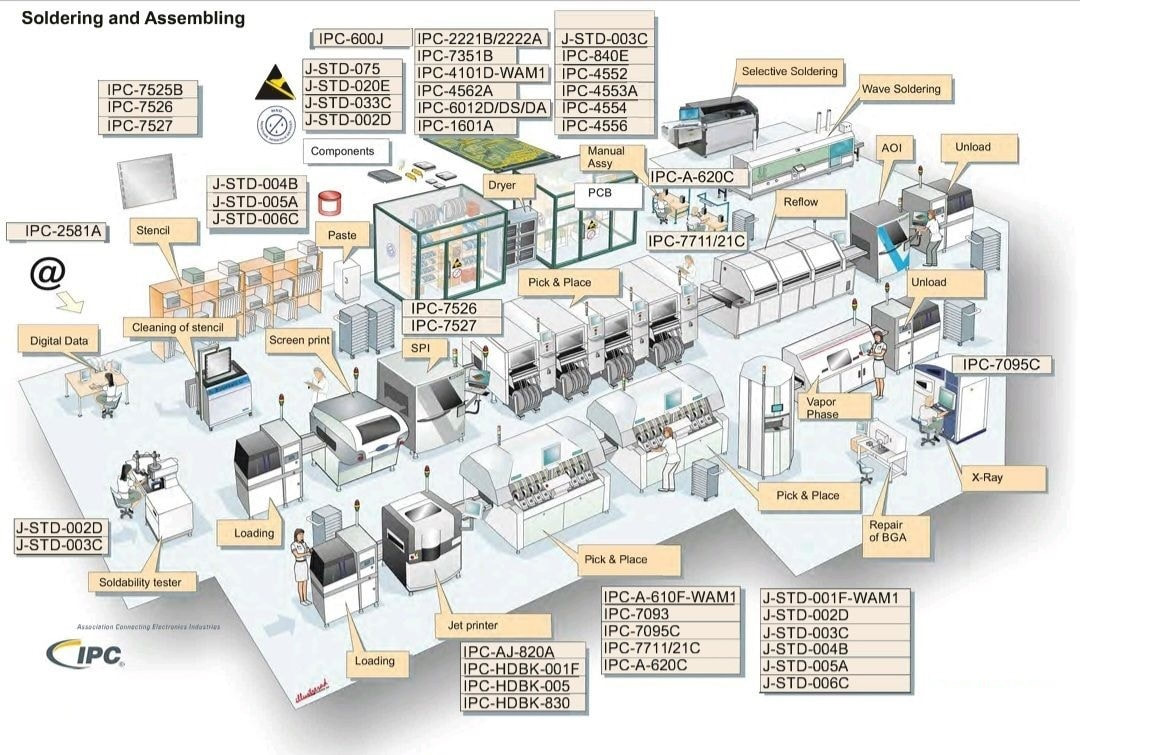

IPC Standards for Soldering and Assembling

The Association Connecting Electronics Industries (IPC) is an organization that sets industry standards for electronics manufacturing and assembly processes. There are various IPC standards that govern different aspects of electronics manufacturing. Some of the important IPC standards include:

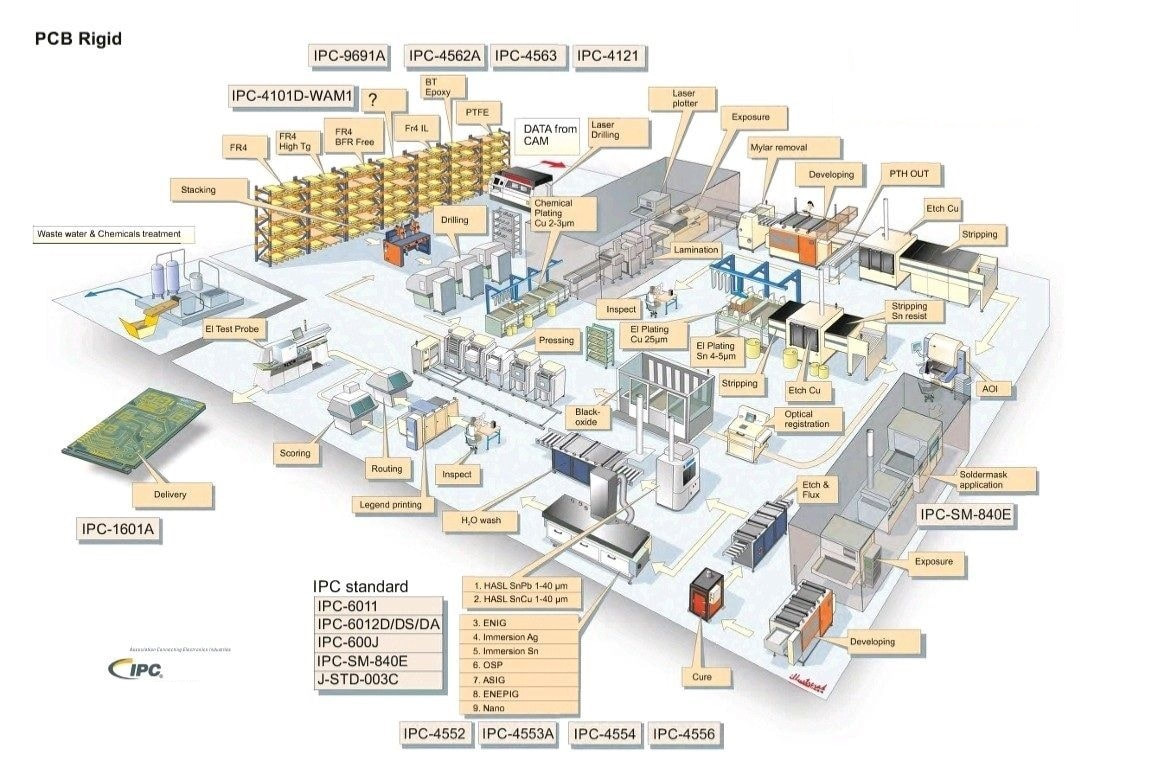

- IPC-A-600: Acceptability of Printed Boards - This standard defines the acceptability criteria for PCBs (printed circuit boards), covering materials, fabrication processes, and inspection criteria.

- IPC-A-610: Acceptability of Electronic Assemblies - This standard establishes the acceptability criteria for electronic assemblies, including soldering criteria, component placement, and various assembly processes.

- IPC-J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies - This standard outlines the requirements for soldering processes, materials, and inspection criteria for electronic assemblies. It is often used in conjunction with IPC-A-610.

- IPC-7711/7721: Rework, Modification, and Repair of Electronic Assemblies - This set of standards provides guidelines for reworking, modifying, and repairing electronic assemblies. IPC-7711 addresses rework of electronic assemblies, while IPC-7721 covers modification and repair.

- IPC-7351: Generic Requirements for Surface Mount Design and Land Pattern Standard - This standard provides guidelines for designing surface mount component land patterns on PCBs to ensure proper soldering and assembly.

- IPC-2221: Generic Standard on Printed Board Design - This standard defines the requirements for the design of printed boards, including layout, materials, and tolerances.

- IPC-6012: Qualification and Performance Specification for Rigid Printed Boards - This standard specifies the performance requirements for rigid PCBs, including material quality, electrical and mechanical characteristics, and reliability.

- IPC-6013: Qualification and Performance Specification for Flexible Printed Boards - Similar to IPC-6012, this standard specifies the requirements for flexible PCBs.

- IPC-620: Requirements and Acceptance for Cable and Wire Harness Assemblies - This standard covers the acceptability criteria for cable and wire harness assemblies, including materials, fabrication processes, and inspection criteria.

- IPC-9252: Requirements for Electrical Testing of Unpopulated Printed Boards - This standard outlines the requirements for electrical testing of unpopulated PCBs, including procedures and criteria.

- IPC-4552: Specification for Electroless Nickel/Immersion Gold (ENIG) Plating for Printed Boards - This standard defines the requirements for ENIG surface finish, which is commonly used in PCBs.

- IPC-T-50: Terms and Definitions for Interconnecting and Packaging Electronic Circuits - This document provides a comprehensive glossary of terms related to electronics manufacturing and assembly.

IPC Standards for PCB Manufacturing

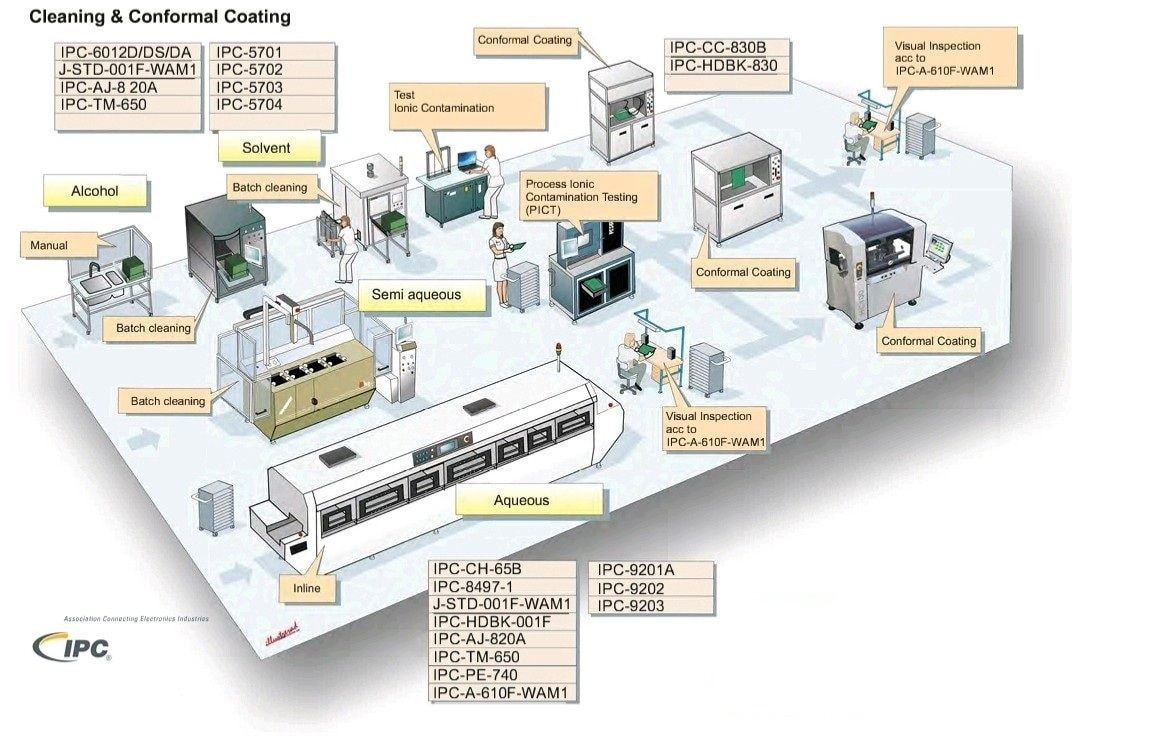

IPC Standards for Cleaning and Conformal Coating

These are just a few of the many IPC standards that exist to govern various aspects of electronics manufacturing processes. These standards help ensure consistency, quality, and reliability in the electronics industry, and they are widely used and recognized by manufacturers, assemblers, and quality control professionals.

|

Return to home page

|