|

|

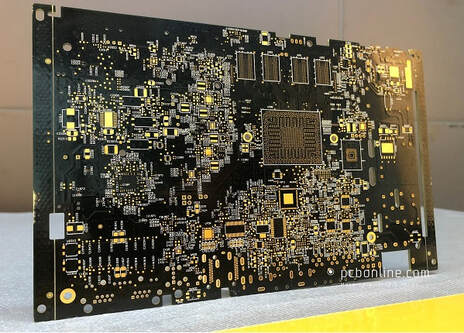

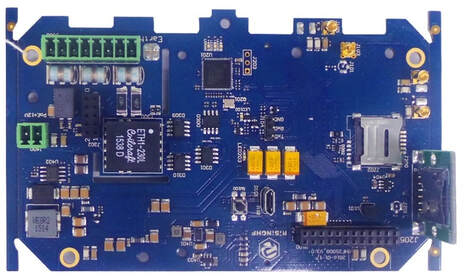

PCBONLINE is a one-stop advanced PCB manufacturer and assembler, working since 1999.

Our service range:

ISO 9001, IATF 16949:2016, REACH, RoHS, and UL certificates

Don’t hesitate to get a quotation from us: [email protected]

Our service range:

- All customized PCB

- Electronic components purchase service

- BOM quote service

- PCB layout/ design

- Factory was set up in 1999, having 100+ experienced engineers, 1500+technicians

- Fast delivery (2 layer PCB can be delivered within 6 hours)

- Fair Transparent Pricing, bulk orders enjoy discount, new users enjoy 100$ off coupons

- Advanced online quotation system, saving your time and energy

- Provide 1 to 1 service for you

ISO 9001, IATF 16949:2016, REACH, RoHS, and UL certificates

Don’t hesitate to get a quotation from us: [email protected]

|

Products & services

|